Not known Details About Premier Aluminum Llc

Not known Details About Premier Aluminum Llc

Blog Article

Not known Details About Premier Aluminum Llc

Table of ContentsThe Greatest Guide To Premier Aluminum LlcExcitement About Premier Aluminum LlcHow Premier Aluminum Llc can Save You Time, Stress, and Money.9 Easy Facts About Premier Aluminum Llc ExplainedPremier Aluminum Llc Can Be Fun For Everyone

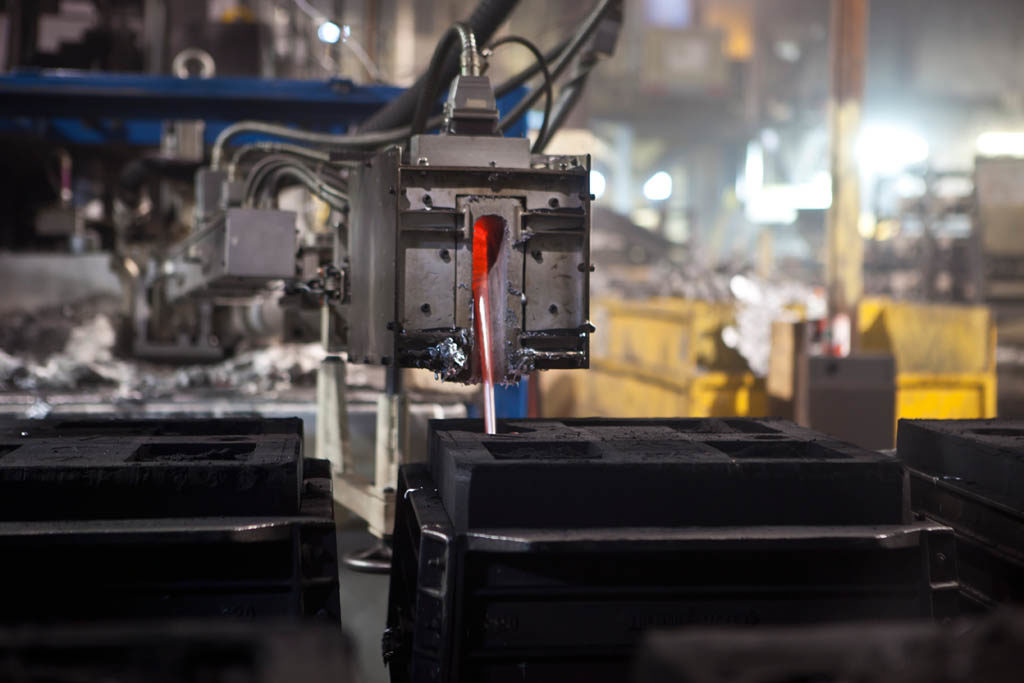

When choosing an aluminum factory for your production demands, it's crucial to study a number of variables. Among one of the most crucial elements to consider is the experience and proficiency of the factory. Picking a foundry who has the best understanding of the light weight aluminum spreading procedure, and the profile to reveal for it, aids to have a successful end result for your task.Having the experience and market knowledge to engineer your spreadings for optimal manufacturing and high quality results will certainly simplify the task. Making light weight aluminum castings needs a facility set of processes to achieve the ideal results. When determining on a brand-new light weight aluminum factory to partner with, ensure they have comprehensive market experience and are well-informed about all aspects of the aluminum spreading procedure: style, manufacturing, product evaluation, and item screening.

The shop should also have a proven performance history of providing outstanding items that fulfill or surpass consumer assumptions. Quality assurance needs to also go to the top of your checklist when picking a light weight aluminum factory. By dealing with a qualified foundry that complies with the standards for quality assurance, you can secure the stability of your product and ensure it meets your specifications.

An Unbiased View of Premier Aluminum Llc

Various components that very complicated shapes can be produced using this process. Prior to you start looking for a trustworthy light weight aluminum pass away wheel, there are some important points that you require to do.

You need to ask on your own what type of light weight aluminum die spreadings you call for. After identifying what you require, you have to state the specifications of the light weight aluminum die spreadings you call for. Identify the weight, density, dimension, and various other specs of the light weight aluminum die-cast you need. It would additionally be far better if you could draw and reveal all the dimensions of the light weight aluminum die-cast.

After having this details, you can start looking into light weight aluminum die-casting producers. You can do this by simply inputting the search phrase" Aluminum die casting suppliers" on the Google search engine.

Several of the questions you need to ask yourself are whether they have actually experienced and well-trained operators, exactly how long their Homepage service has actually functioned, or if they have some success. You can frequently get the solution to these inquiries from the producer's site. You can look into other web sites or outside resources to validate if the info given on the producer's site is genuine.

The 8-Minute Rule for Premier Aluminum Llc

One more thing you have to think about is the producer's capability to produce light weight aluminum die-casting products. Simply put, the quantity of products the manufacturer can generate at a provided time. Several of the important inquiries you require to ask on your own are whether the maker can create a higher quantity or can the maker satisfy your demands.

(https://sandbox.zenodo.org/records/142041)Suppose your firm calls for 10,000 pieces of particular device parts from the manufacturer within one month? You purchased this quantity; nonetheless, the manufacturer can only create 5000 items of these maker components within one month (Aluminum Casting). Because of this, you won't have the ability to get the quantity that you get in a timely manner

Rumored Buzz on Premier Aluminum Llc

It is crucial that you need to make inquiries if the maker is applying an in-house tooling procedure. Furthermore, you need to ask the producer just how much the cost of internal tooling is. Bear in mind that the in-house tooling process, which allows you to produce distinct designs and shapes can be an additional cost.

This element directly correlates with the producer's manufacturing ability. You have to seek a producer that can guarantee quicker shipment of products. Nevertheless, this must be performed in such a manner in which top quality criteria are maintained. This can ensure that you can obtain your items on time, and you can stay clear of missing out on those important organization opportunities.

This indicates that there are numerous options that you can select from. Today, client needs go on altering. It seems that customers are looking for a superb combination of quality, cost-effectiveness, and longevity. That is why it is substantially recommended that you must pick a producer that can create different kinds of light weight aluminum die-cast items.

The Basic Principles Of Premier Aluminum Llc

Most usually, these aluminum die-casting products will require some decors, machining, or completing touches. Having this in mind, you must seek a supplier that can execute a range of additional finishing jobs once die casting is done. Some instances of finishing procedures consist of Chromating, CNC Machining, Sandblasting, Powder layer, Anodized, E-coating, Wet paint, Plating, and a lot more.

Die casting is one of the most affordable, precise, and protean production procedures in the globe minute. The process involves suitable molten essence, under stress, right into an appropriate die (planet), and formerly strengthened it can be expelled and ended up (if needed) in a variety of means. Report this page